How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

Steel construction systems are frameworks that rely on steel’s durability, flexibility, and strength to support the loads and stresses of buildings and structures.

Light-gauge steel framing uses lightweight yet strong cold-formed steel sections, which are ideal for residential and light commercial buildings. These frames are used for walls, floors, and roofs, providing a durable alternative to wood framing.

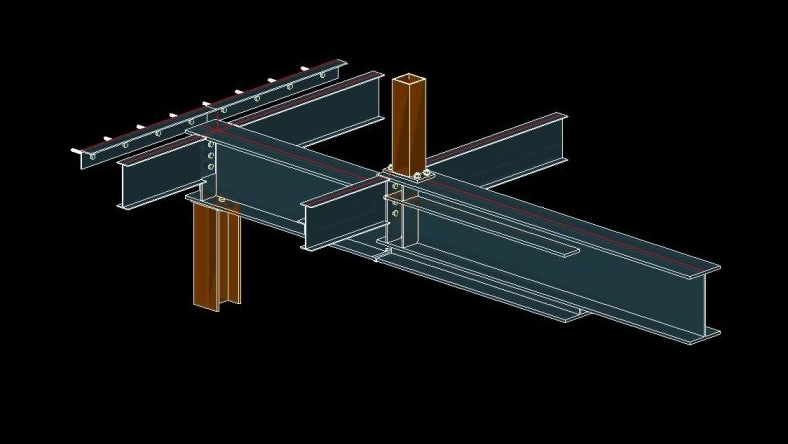

Structural steel is specifically designed for construction and formed into widely used shapes such as I-beams and H-beams. With its high load-bearing capacity, durability, and ability to span large distances, structural steel is often used in extensive, complex structures such as high-rise buildings, bridges, and industrial facilities.

Cold-formed steel construction benefits midrise buildings with its excellent load-bearing capacity and resistance to environmental conditions. Shaped at room temperature, components are strong, flexible, and suitable for multistory structures.

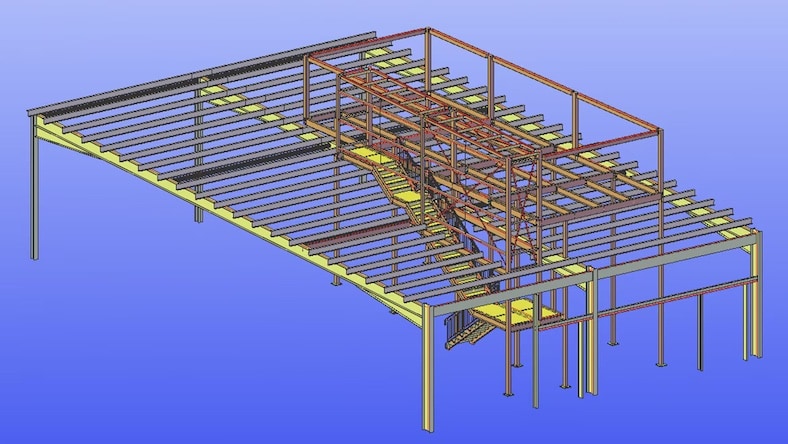

Steel framing systems have revolutionized modern architecture, allowing innovative and complex designs. Their high strength-to-weight ratio, durability, and versatility enable larger spans and open spaces, enhancing contemporary buildings’ aesthetics and functionality.

Trusses and joists are fundamental in steel construction. Trusses support roofs and bridges with triangular units that distribute loads efficiently, which is ideal for large spans. Joists, used for floors and ceilings, are preferred for regular floor layouts due to their simplicity and ease of installation.

Prefabricated steel solutions involve offsite manufacturing and onsite assembly, reducing construction time and waste and ensuring higher quality control. This approach is favorable for large-scale projects where speed and precision are critical.

Engineering steel structures involves meticulous planning and precise safety, stability, and performance calculations. Key factors include:

Designing steel structures involves several critical aspects:

Steel component manufacturing involves:

Steel framing systems are desirable for a range of construction projects, offering many advantages, including:

Steel framing systems support heavy loads and large spans, enhancing stability and safety.

Steel framing systems allow innovative designs with wide-open spaces and easy modifications for future changes.

Prefabrication and quick assembly of steel construction systems reduce onsite construction time and labor costs.

Precision manufacturing of steel framing systems minimizes waste, and steel’s durability reduces long-term maintenance costs.

Using recycled steel reduces the environmental impact of construction; prefabrication of steel construction systems can also reduce energy consumption during the building process.

Steel maintains structural integrity at higher temperatures compared to other materials and is resistant to extreme natural conditions such as high winds and seismic activity.

Navisworks Manage, Navisworks Simulate software and the Navisworks Freedom 3D viewer for 5D analysis, design simulation, and project review.

LAWTON WELDING CO. LTD.

A structural steel company uses Autodesk Advance Steel to transform an 1874 stone church into a residential development in Boston.

Image courtesy of Lawton Welding, Co., Ltd.

GRAEF

An engineering planning and design firm uses Autodesk Advance Steel and the Autodesk Architecture, Engineering, and Construction Collection to deliver higher-quality projects faster.

Image courtesy of GRAEF

STEEL PRECISION GROUP

A structural steel detailing company uses Autodesk Advance Steel, Revit, and Navisworks to ensure seamless collaboration, more accurate detailing, and efficient project execution.

Image courtesy of Steel Precision Group

Learn how to make the most of BIM data for steel detailing and fabrication, using advanced software to stay ahead in the structural engineering field.

Master a new workflow using Autodesk Revit, Robot Structural Analysis, and Advance Steel to progress from design to fabrication.

Learn the essential approaches for managing large projects efficiently with Advance Steel.

A steel framing system is a construction method that uses steel components as the primary structural framework for buildings and structures. Known for their high strength-to-weight ratio, durability, and flexibility, these systems involve steel beams, columns, and joists to create a robust skeleton that supports and transfers loads.

Steel framing is resistant to pests, rot, mold, fire, and extreme weather, ensuring a longer lifespan and enhanced safety. It allows precise, quick assembly and can be easily modified or expanded. Steel framing systems are integral to modern construction, offering efficiency and sustainability.

The two most common steel structural systems are light gauge steel framing and structural steel framing. Light gauge steel framing uses thin, cold-formed steel sections, making it ideal for residential and light commercial buildings due to its lightweight yet strong nature, similar to wood framing but more durable.

Structural steel framing, involving heavier, hot-rolled steel sections like I-beams and columns, is used in larger, complex structures such as high-rises, industrial buildings, and bridges. This system offers superior load-bearing capacity, design flexibility, and the ability to span large distances without numerous support columns.

Steel construction systems reduce project costs and timelines by offering material efficiency, lower labor expenses, and enhanced durability, which leads to reduced maintenance costs. Prefabrication of steel components allows for simultaneous site preparation and off-site fabrication, speeding up the construction process. Quick on-site assembly, reduced weather-related delays, and advanced steel construction software tools like Autodesk Advance Steel and Revit help streamline design and engineering, further accelerating project timelines. These advantages make steel construction systems effective for modern building projects, enhancing overall efficiency and profitability.

Various types of steel are used in construction, each selected for specific properties.