Product design is the process of imagining, creating, and iterating on solutions that solve problems for customers in commercial sectors like industrial machinery or automotive manufacturing, or directly for the public in sectors such as consumer products.

The product design process begins with research to understand the market and customer needs. Designers use knowledge, empathy, and creativity to conceptualize solutions.

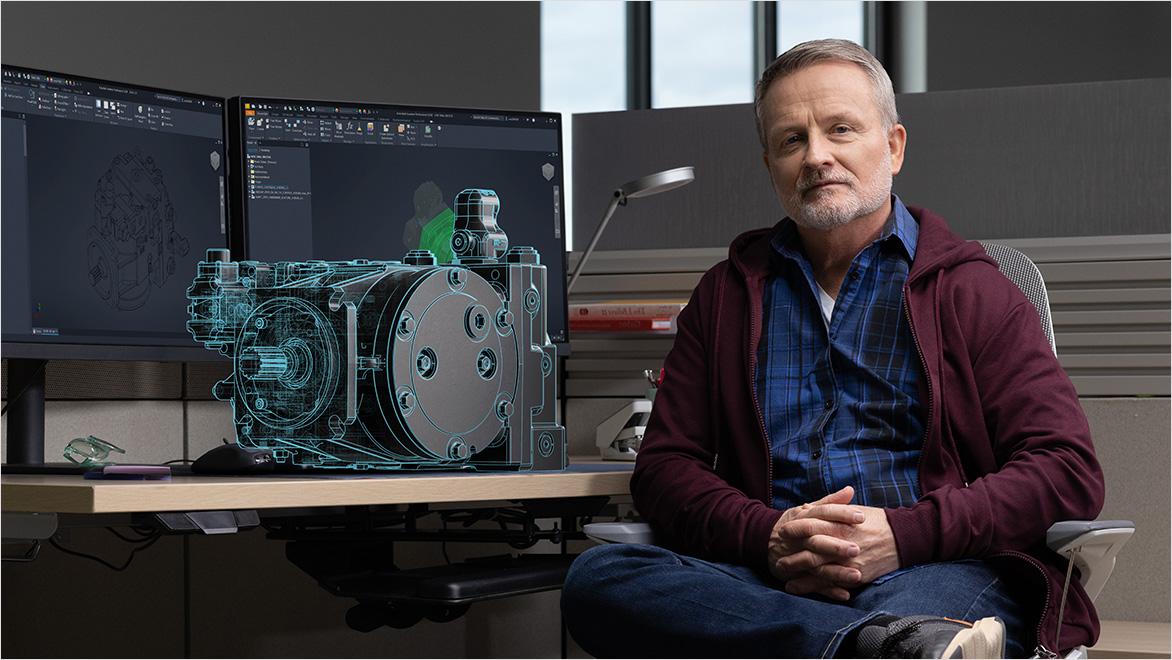

Hand sketches, prototypes, technical drawings, and 3D models are created to communicate and review the proposed product design solution and to coordinate the design process among stakeholders. Further prototyping is used to test and validate concept designs with real customers.

The final output is a product requirements document, specification, technical drawing, and visuals. Typically, product designers work with design engineers to develop concept designs ready for manufacturing.

Jobs in product design could include design manager, industrial designer, product designer, UI/UX designer, graphic designer, animation designer, design engineer, technical designer, design drafter, CAD designer, and CAD operator.