How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

Autodesk process plant solutions enable you to:

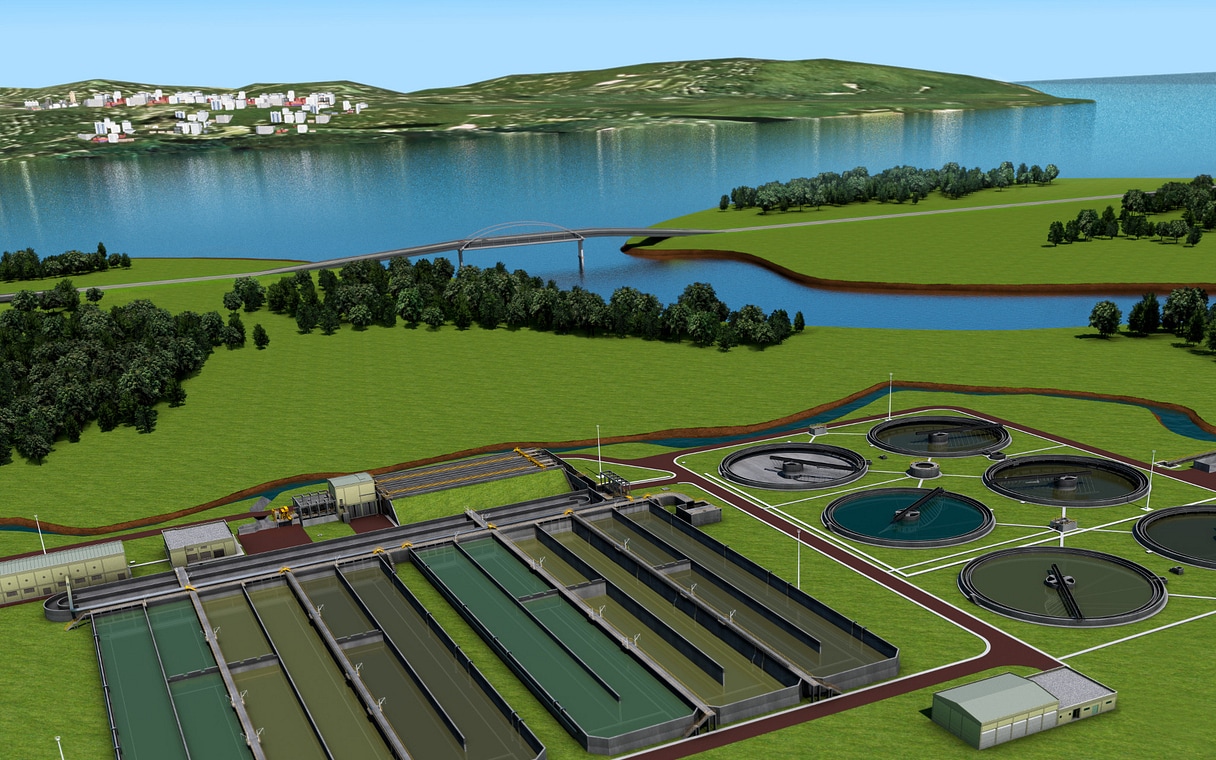

Speed up water and wastewater project start-up with integrated tools for site preparation and piping, equipment and structural design, and modeling.

Quickly model complex brownfield and turnkey projects for oil and gas, streamline multidisciplinary teamwork, and reduce overall costs.

Fast-track pharmaceutical plant projects with spec-driven tools to deliver customized equipment and integrated solutions.

From project concept to completion, more effectively meet your customers’ requirements for safety and hygiene of their food and beverage plants.

See how Autodesk Info360 Plant can solve operational issues in water quality reporting.

Process Pipeline Services used the Plant 3D toolset to spot conflicts, manage changing plans, and save time.

BIM and cloud collaboration allowed Arcadis to boost a water treatment plant’s resilience and ensure safe water.

Comprehensive 3D models make it possible to create and handle all project information throughout the asset’s lifecycle. Gain insights faster, improve multidisciplinary team coordination, and avoid data loss and inaccuracy.

Connect people, data, and processes across the project lifecycle in a cloud-based, common data environment. Expand beyond the office; work together anytime, anywhere. With transparent workflows, you can reduce distractions and errors, and increase capacity. And with a centralized source of truth, you can eliminate siloes, improve access to data, generate insights, and enjoy complete oversight.

With the AEC Collection, empower your plant with the ability to deliver more sustainable infrastructure. Connect multidisciplinary teams to support projects that provide enhanced environmental, social, and economic advantages.

Digital twin technology in Info360 Plant creates more efficient water and wastewater treatment plants that use fewer chemicals and energy, providing better water for local communities.

With Info360 Plant, improve the operational efficiency of your water and wastewater treatment plants to meet regulatory requirements. Use real-time data analytics and cloud solutions to extract actionable insights from plant sensor and IoT data.

2D and 3D CAD tools, with enhanced insights, AI-automations, and collaboration features. Subscription includes AutoCAD on desktop, web, mobile, and seven specialized toolsets.

Cloud-based design co-authoring, collaboration, and coordination software for architecture, engineering, and construction teams. “Pro” enables anytime, anywhere collaboration in Revit, Civil 3D, and AutoCAD Plant 3D.

Plan, design, construct, and manage buildings with powerful tools for Building Information Modeling.

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

In this study, the Plant 3D toolset boosted productivity by up to 74%,* bringing significant time savings to common AutoCAD plant design tasks.

WEBINAR

See how cloud-based operational analytics in Info360 Plant can help optimize water treatment processes.

PUBLIC ROADMAP

Explore the feature development pipeline for civil infrastructure products such as Civil 3D, InfraWorks, Revit, and ReCap Pro. You can provide feedback and input, and upvote your favorite features.

BLOG

See new features in Info360 Plant, including analytics template libraries, compliance-ready data export tools, and more.

Get a closer look at P&ID (Piping and Instrumentation Diagram), a feature in the Plant 3D toolset that helps design the layout of engineering process systems.

Plant designers use the Plant 3D toolset which is included as part of an AutoCAD subscription.

Benefits of plant design software like the Plant 3D toolset in AutoCAD include centralized project data and BIM workflows, such as automated drawing generation based on the 3D model, spec-driven piping, and P&ID creation.

Process plant engineering involves the design, development, construction, and operation of industrial facilities to produce materials or chemicals on a large scale. It aims to optimize processes, ensure safety, select suitable equipment, and manage projects efficiently. The field spans industries like oil and gas, water/wastewater, power generation, pharmaceuticals, semiconductors, and food and beverage processing. Engineers collaborate across disciplines like chemical, mechanical, electrical, and civil engineering to achieve efficient and cost-effective production while adhering to safety and environmental standards.

Plant engineering software is used by a wide range of professionals, ranging from plant engineers responsible for overall plant design and operation, process engineers optimizing industrial processes, and mechanical, civil, and electrical engineers designing specific systems within the plant. For example, the Plant 3D toolset, included as part of AutoCAD, enables plant designers to create and edit piping and instrumentation diagrams (P&IDs), and to generate and modify process plant models, which they use to produce piping isometrics and piping orthographic drawings.

In addition, project managers, engineering services, compliance managers, operations managers, engineers, on-site staff, and executive decision makers use software to monitor and optimize plant operations. For example, Autodesk Info360 Plant is a cloud-based operational analytics solution designed for water and wastewater treatment plants to improve real-time data analysis and enable workflows associated with performance, compliance, and improvement planning.

The Plant 3D toolset within AutoCAD produces all relevant documents from P&ID schematic flow diagrams, 3D models, Plan and Sections, right through to fabrication and construction documents like Isometrics and Spool drawings. You can use Revit to model the facilities that hold the pump and treatment equipment, and Navisworks Manage to detect and manage clashes between pipes and facility structures. All these tools and more are available in the Autodesk Architecture, Engineering & Construction Collection.

A digital twin is a virtual replica of a physical asset that is updated in real time to represent its live characteristics. It is a virtual reality where process plant engineers can experience and ask what-if questions to simulate scenarios to help them solve problems, train staff, meet challenges, increase efficiency, reduce expenses, and improve service.

The water industry, for example, is increasingly using digital twin technology to simulate and test scenarios virtually to help utilities address them in real-world environments. According to the latest definition from the American Water Works Association (AWWA), a digital twin is “a dynamic digital representation of real-world entities and their behaviors using models with static and dynamic data that enables insights and interactions to drive actionable and improved outcomes.”

Smart process plant solutions help automate busywork, simplify, and improve operations. With the right solution, you can:

Access, connect, capture, and visualize data

Measure, analyze, and calibrate

See the future with predictive analytics

Optimize in real time with prescriptive analytics

Gain collective intelligence

New software as a service (SaaS) platforms like the Autodesk Info360 Plant application make it possible for process plants to power digital twin initiatives by converting raw data from SCADA and IoT systems into an actionable dashboard and digital workspaces that you can use to manage critical plant events, incidents, and KPIs. It unifies plant data in the cloud and applies sophisticated analytics, data modeling, and alerting tools to make operational information more accessible, reliable, and actionable.

Key functionalities like custom dashboards, data cleanup, and automated KPIs help you visualize, monitor, and understand your system. Providing subject matter experts with data analytics tools can enable creative solutions to complex projects that encourage productivity, reduce costs, and support a positive organizational culture. Often, in using industry data tools, users find creative ways to repurpose these strategies for desired business outcomes.

Real-time data monitoring and analysis manage and mitigate operational risks, enable interactive facility process flow diagrams, and deliver consistent and efficient management, sustainability, and compliance reporting.

Info360 Plant is a cloud-based operational analytics solution within the Info360 platform designed specifically for water and wastewater treatment plants, water utilities, and industrial owned plants to improve real-time data analysis and enable workflows associated with performance, compliance, and improvement planning.

As a workflow solution with enterprise-level technology, it enables repeatable plant workflows like chemical process sustainability and energy audits, replacing spreadsheets and paper-based processes. Users can access asset performance data and analysis to perform daily operations such as maintenance, sensor calibration, process optimization, and capital improvement planning.

Info360 Plant enables plant owners, operators, and engineers to increase their insights through data to improve operational cost management and overall plant performance, and reduce energy, chemical usage, and environmental impacts.

Productivity data based on a series of studies commissioned by Autodesk to an outside consultant. The seven toolset studies compared basic AutoCAD to the specialized toolsets within AutoCAD when performing tasks commonly done by experienced AutoCAD users. As with all performance tests, results may vary based on machine, operating system, filters, and even source material. While every effort has been made to make the tests as fair and objective as possible, your results may differ. Product information and specifications are subject to change without notice. Autodesk provides this information “as is,” without warranty of any kind, either express or implied.