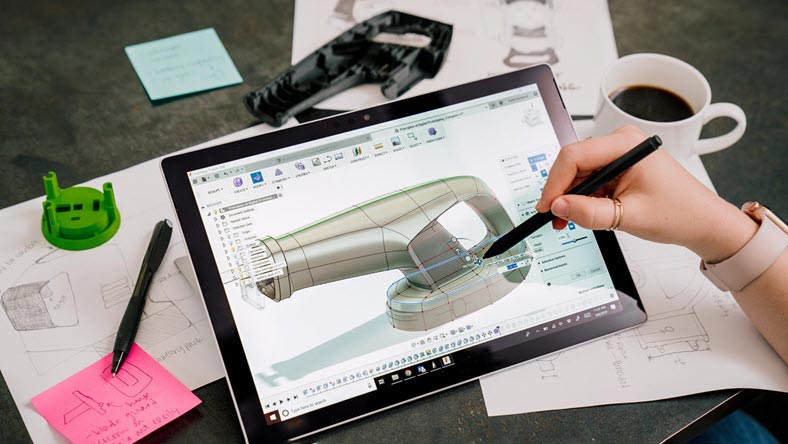

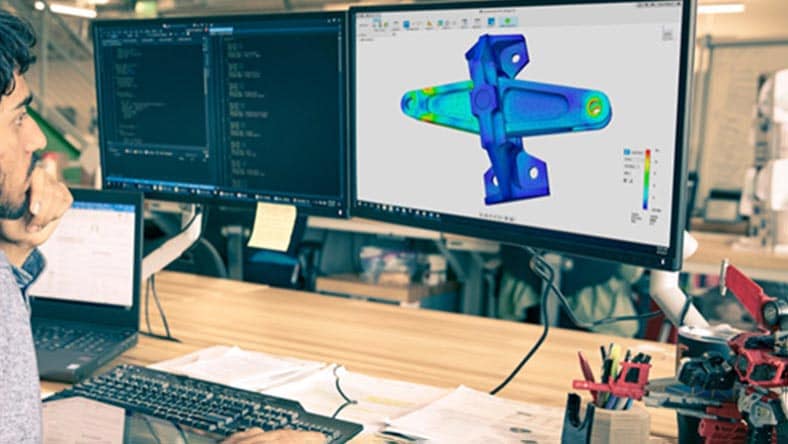

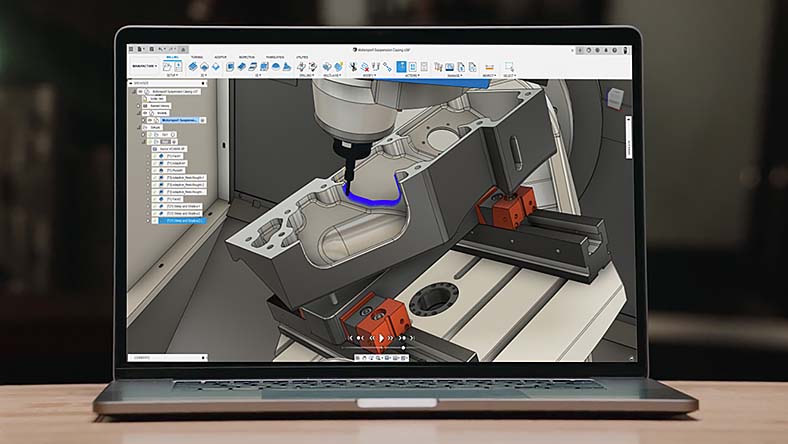

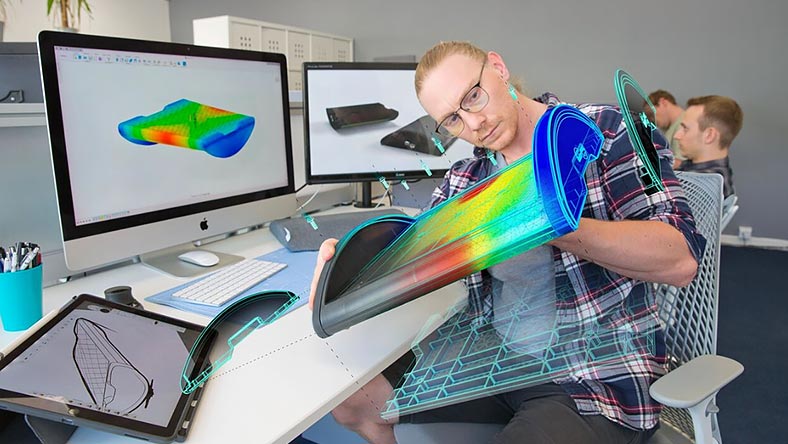

CAD (Computer-Aided Design) software is a key tool utilized in mechanical engineering. It allows engineers to create precise 3D models, conduct simulations and analyses, and even control manufacturing processes. Autodesk Fusion is a leading example of a comprehensive CAD software platform.

- AutoCAD

- Revit

- Civil 3D

- AutoCAD LT

- BIM Collaborate Pro

- Inventor

- Fusion

- Fusion extensions

- Navisworks

- 3ds Max

- Maya

- Arnold

- Flow Capture

- Flow Production Tracking

- View all products

- View Mobile Apps

- Architecture, Engineering & Construction

- Product Design & Manufacturing

- Media & Entertainment

- Buying with Autodesk

- Pay as you go with Flex

- Special offers

- Help with buying

- Industry solutions

- Educational access

- Start a trial

- Download your software

- Download file viewers

- Product support

- System requirements

- Download your software

- Updates

- File viewers

- Students and educators

- Installation

- Account management support

- Educational support

- Partner Finder

- Autodesk consulting

- Contact support

- Learning

- Certification

- Training

- Autodesk University

- Conferences and events

- Success planning

- Coaching

- Autodesk Community

- Groups

- Blogs

- Developer Network

- Autodesk Customer Value

- 0

- ASEAN (English)

- Australia

- België

- Belgique

- Brasil

- Canada (English)

- Canada (Français)

- Česko

- Danmark

- Deutschland

- España

- Europe (English)

- France

- Hong Kong (English)

- India (English)

- Italia

- Latinoamérica

- Magyarország

- México

- Middle East (English)

- Nederland

- New Zealand

- Norge

- Österreich

- Polska

- Portugal

- Singapore (English)

- Suomi

- Sverige

- Schweiz

- South Africa (English)

- Suisse

- Svizzera

- Türkiye

- United Kingdom

- United States

- 中国大陆地区

- 台灣地區

- 日本

- 한국