How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

The Industrial Internet of Things employs cloud computing to connect systems.

The Industrial Internet of Things (IIoT) is part of an Industry 4.0 approach. In this cloud computing environment, factories and plants use instruments and systems to produce, collect, and report on operational data.

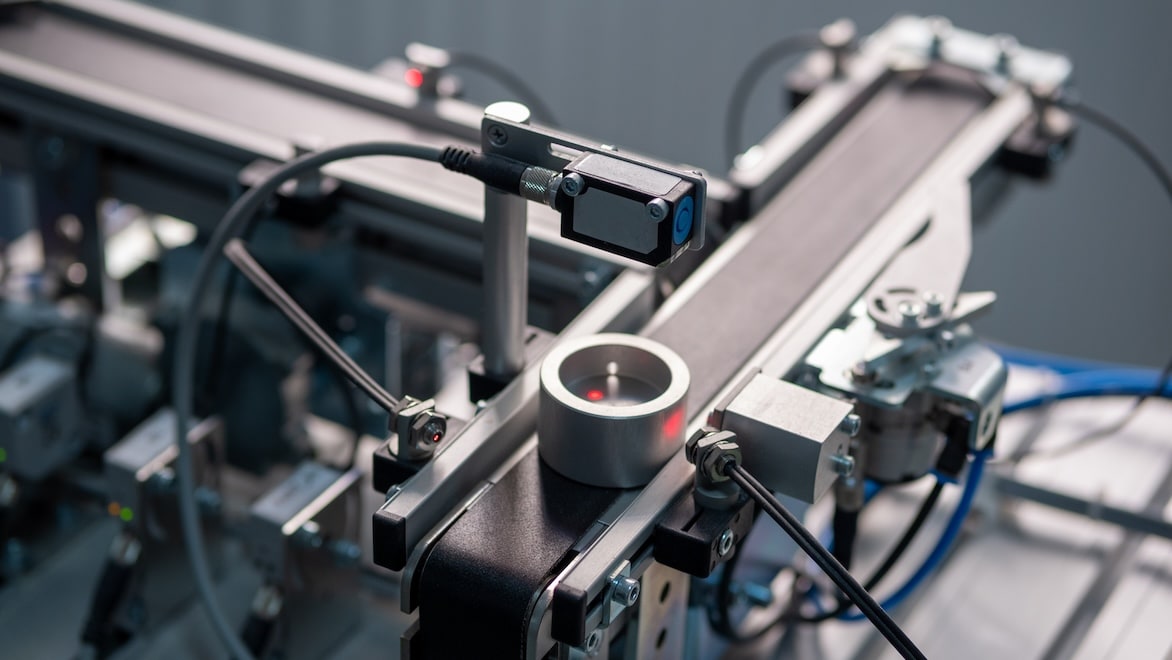

Networked sensors, like the ones on this factory assembly line, are at the core of the Industrial Internet of Things.

In any given IIoT operational environment, a collection of networked devices and sensors communicate constantly with each other, generating and transmitting real-time data. The devices may be entire units within the industrial infrastructure, or they may be an auxiliary system installed on a machine, vehicle, or device. All data is transmitted to a central system which processes the data and creates actionable reports and optimizations based on the data that flows to it.

The detailed data and reporting from IIoT sensors enable facility managers to make informed, proactive decisions about operations.

Every production line or plant has countless tools and processes, each of which can use sensors to collect performance readings. That sensor information is collected and sent to IIoT software applications that analyze and produce an overall, data-driven view of how your entire operation is performing. User-end UIs then provide a window into the results.

These IIoT data points and UI tools can manage production by providing reports and solutions for supply inputs, component breakdown, scheduling part replacements, and adjusting production speed to match demand.

Manufacturing and utilities that rely on cloud-connected devices to monitor operations are part of the IIoT.

While the Internet of Things (IoT) tends to refer to domestic and commercial applications of networked devices and sensors, the Industrial Internet of Things (IIoT) refers to these devices in the industrial workspace. The Internet of Things generally refers to connected sensors and instruments in domains such as smart homes, business processes, and personal health tools. The Industrial Internet of Things usually includes devices in agricultural, mining, manufacturing, and utilities settings, and these often feed a continuous stream of operation data—in contrast to IoT devices that may communicate more sporadically on user request.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

The Industrial Internet of Things connects your physical and digital operations. As the physical and digital operations watch, report on, and influence each other, the result will be deeper insights into how your business is performing.

With IIoT information direct from your tools and products—even post sales, in some cases—you’ll have an overall, picture of their performance under real-world conditions. The insights garnered from the Industrial Internet of Things will let you create and optimize designs to deliver improved performance for each new generation, using everything that’s come before to inform your process.

Automated sensors in lights, HVAC, and water systems can provide the right resources for a single building or an entire city. IIoT smart meters can track and report usage, while cameras or motion sensors can detect the presence of a person to automatically control lights or A/C systems, reducing unnecessary usage.

Your systems and tools can collect and monitor data about their use and state of health, both in absolute terms and within their operating environments. That means you’ll have a live, real-time view of objects or parts nearing the end of their usable lifecycle, letting you repair them or install replacements before a product breakdown causes an expensive process-wide stoppage.

A fleet of products that are already in the marketplace can expand and open revenue streams. An Industrial Internet of Things object that reports its performance presents countless opportunities. You might offer the user a service or replacement, remote monitoring, or product-specific firmware updates in a timely manner that minimizes disruption.

Sensory performance data collected onboard the product and across supply chains will provide customers with information on updates and alternative uses, advice on proper tool care to extend the tool’s life, and more.

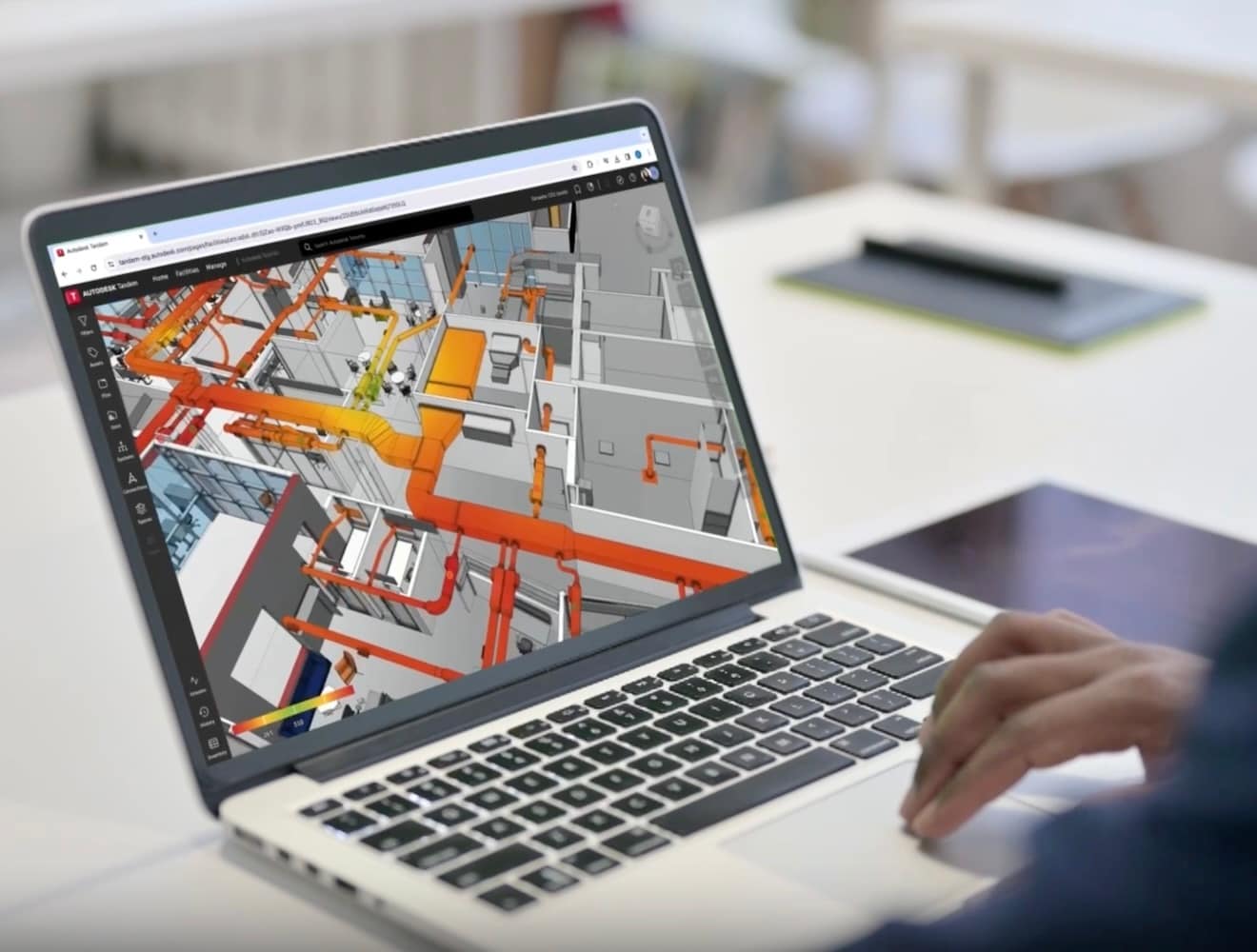

By creating a more accurate model of a system such as HVAC, Autodesk Tandem’s digital twin capabilities make it possible to track and monitor assets with IIoT sensor data in real time.

Autodesk Research has long pioneered technology that supports IIoT solutions, enabling users to access historical and real-time sensor data so that it can be integrated into visualization components.

MOICON

With the help of Autodesk Platform Services, this technology company’s innovative browser-based digital twin software improves the factory floor operations and performance of smart manufacturing facilities.

PINTO BRASIL

This metalworker for automotive and other industries has reduced lead times, improved automation, and increased the standardization and control of its smart manufacturing operations using Autodesk tools.

Image courtesy Pinto Brasil

ANDRITZ

Industrial engineers at this Austrian design firm created a paper mill production line integrating 3D-modeled digital twins of every component, with sensor data and AI working to monitor the entire factory.

Image courtesy of ANDRITZ

Machine learning can interrogate IIoT results just like human managers can—and sometimes does an even better job, helping streamline everyday tasks such as identifying errors and improving efficiency in future production runs.

Industrial Internet of Things solutions don’t just apply to big plants or factories. IIoT sensors and instruments will fit more functionality into smaller spaces for use in personal electronics carried in pockets or worn on wrists.

With the Industrial Internet of Things, every industry device generates operating data, enabling interoperability and improving safety, cost efficiency, and sustainability.

As more companies adopt IIoT processes, they will increasingly integrate AI and machine learning.

While it’s a relatively new addition to the industrial space, the IIoT has already had a dramatic impact. But what might the Industrial Internet of Things trends of the future be? In the near term, expect to see greater integration of artificial intelligence and machine learning, faster communication through 5G technology and beyond, and real-time location systems that track and locate assets, personnel, and equipment within the industrial environment. A combination of AI and IIoT sensor technology may also make predictive, rather than preventative, maintenance the new norm.

Find out how Autodesk’s research team is developing new technologies that will continue to push forward Industrial Internet of Things solutions.

An IIoT solution has four layers:

Absolutely, provided you plan an IIoT framework, such as a corporate network, with cybersecurity in mind.

IIoT refers to the network of devices and instruments that use sensors and software over a communications network to report on performance and give you an up-to-the-minute view of assets and processes.

Industry 4.0 is a larger business approach that blends IIoT software with other technology, including robotics, automation, AI, and machine learning.