How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

High-fidelity prototypes are made to be as close to the finished product in appearance, materials, and function as possible.

A high-fidelity prototype is a detailed representation of a product, usually created later in the design phase, that works, looks, behaves, or moves as closely as possible to the intended final product. It makes development faster and cheaper and gives stakeholders a more tactile representation of the product to interact with.

Iterative design and additive manufacturing are transforming the way product designers build and test prototypes. Image courtesy of Under Armour.

In the pre-digital industrial and product design era, prototyping was done by specialized artists who took schematics or sketches on paper and built physical versions out of materials from resin to clay and anything in between.

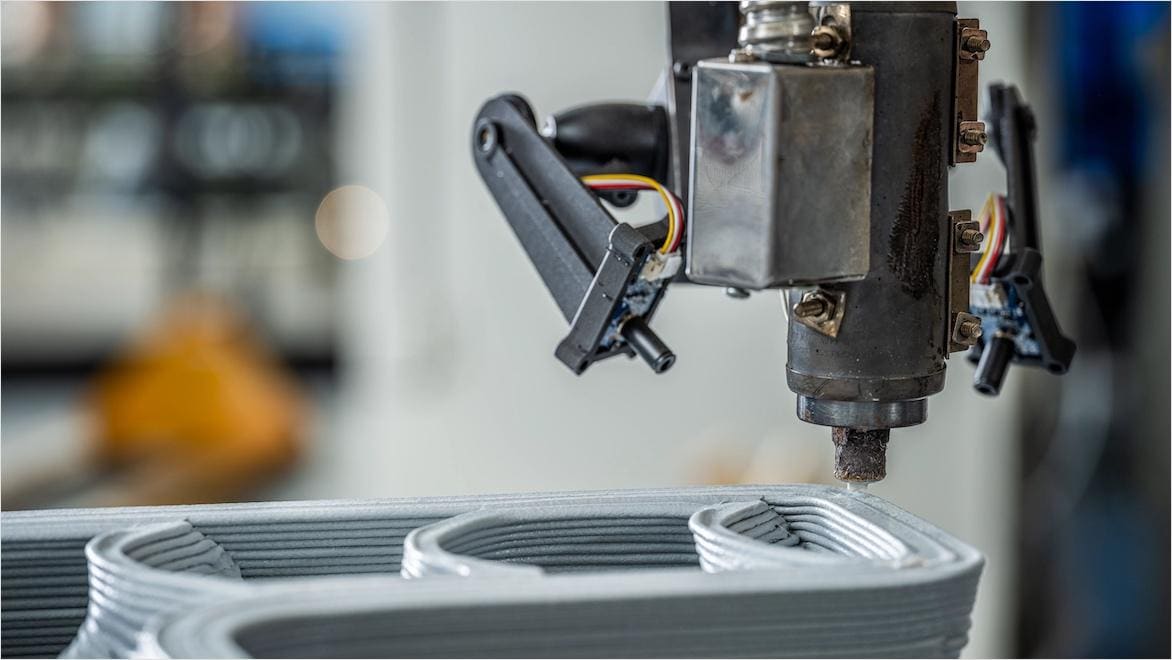

Additive manufacturing (3D printing) has upended prototyping by enabling iterative design processes. A 3D design can be simulated, iterated, and approved in prototyping software before a real-world object is made. The precise nature of digital design and 3D printing means designers or engineers can create a high-fidelity prototype with all the detail the final product is intended to have.

Different design stages call for different levels of detail, and there’s still very much a place for low-fidelity prototyping. It’s usually most relevant early on when the design process is focused on targeting and articulating overarching goals in user experience. High-fidelity prototype tools are valuable in later stages when designers and engineers are ironing out the finer details of functionality and product-application fit.

3D printing can be a cost-effective method for producing high-fidelity prototypes.

At its heart, prototyping is a conversation between the designer and the future user. The former asks the latter what works and what doesn’t and refines the design as the conversation progresses.

The initial design considerations might simply be questions about how easy to use a design must be. As projects move to high-fidelity prototyping, the design must grow more precise to reflect what designers have learned and iterate from there.

3D printing is one of the cheapest, most effective methods to transition from an approved digital design to a prototype because it lets designers test a tangible, tactile representation of the product.

High-fidelity prototypes allow designers, customers, and other stakeholders to interact with a physical product that closely approximates the final manufactured product.

The first stage in design should always ask “how will this make the user’s/customer’s life easier?” Once the basic design is established, rapid, iterative prototyping allows stakeholders to work out the finer details.

Aside from variables like manufacturing volume and materials, a high-fidelity prototype will be a physical object that looks, feels, and behaves the closest to the final product after it rolls off the production line as possible. Because high-fidelity prototype tools create an object with nearly the same level of detail as the final design, they offer project leaders a clearer idea of the time and cost required to manufacture the final product.

The leap from a high-fidelity prototype to a finished product is among the shortest in the development cycle for several reasons:

Users of the intended end product get a more faithfully rendered version than they ever could from drawings or digital models. This means their interactions with the high-fidelity prototype will be as close as possible to how they’ll behave with the final product, helping them provide more targeted feedback.

Prototypes in other mediums—no matter how detailed—can’t reveal every nuance and idiosyncrasy of real-world use. High-fidelity prototypes are truer to the final product, thus minimizing the risk of errors or design flaws emerging in the finished product and requiring costly redevelopment.

Engineers or designers might be able to form a mental picture of the final product from a sketch or digital model, but not everybody can. Sometimes the surest way to get investors, managers, and intended customers excited about a product is by creating a tactile representation of it in the real world. High-fidelity prototyping gives stakeholders something to interact with that’s all but indistinguishable from the final product.

Designers, engineers, and developers can use iterations of the design at every stage to increase the functionality of the product. High-fidelity prototyping gives them more accurate points to start from and helps streamline the development process. Using a more faithful rendition of the design also leads to a faster appreciation of how a product’s functions and usage metrics will affect each other.

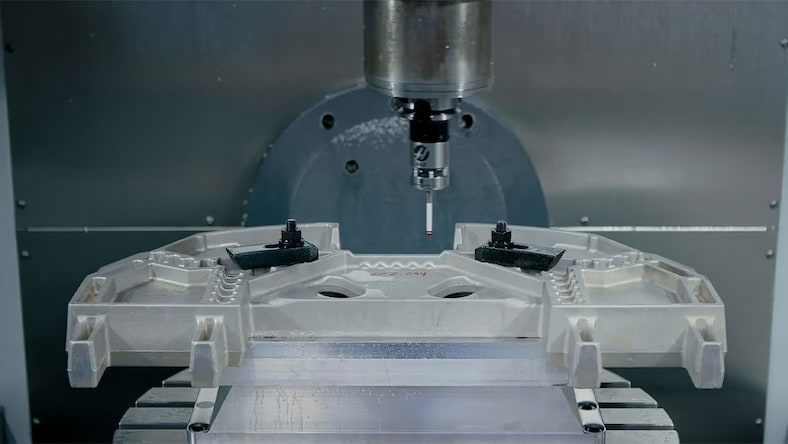

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

With engineering, design, marketing, managerial, and testing teams all involved in major projects, prototyping is rarely linear, so a tool that manages the workflow between departments is critical. Autodesk Fusion takes projects from an idea to a high-fidelity prototype quickly and seamlessly.

An expert explains the opportunities prototyping offers and the steps to adopt it in design and engineering.

Learn the essential stages of product development and the ways that Autodesk Fusion can support every step of the process.

CONTURO PROTOTYPING

See how Conturo uses the Autodesk Fusion Manufacturing Extension to develop high-fidelity prototypes and small-batch production runs for aerospace, automotive, and medical manufacturers. Fusion’s advanced 5-axis CNC-machining capabilities help Conturo shorten its clients’ development times and bring products to market faster.

NICHINAN CORPORATION

Prototype design and manufacturer Nichinan Corporation uses Autodesk Fusion to bring design, rendering, and analysis for its high-fidelity prototypes and packaging into one platform for easy real-time collaboration.

KISKA

International design firm KISKA took inspiration from the iconic 1950s Husqvarna Silverpilen (Silver Arrow) motorcycle to create the new Husqvarna SVARTPILEN (Black Arrow) and VITPILEN (White Arrow) models. See the “inside-out” approach the firm took to bring these modern bikes from sketch to high-fidelity prototype to finished product.

Image courtesy of KISKA.

A high-fidelity prototype is a rendition of an object or workflow with the highest possible level of detail, comparable to the final product for testing and performance assessment.

Low-fidelity prototyping, often used earlier in the design process, establishes overarching design and usability goals for a design or concept.

High-fidelity prototyping is typically used in the final stages of product development to identify and iron out finer details about how users will interact with a product.

The three levels of prototyping are low, medium, and high.

High-fidelity prototyping offers several advantages over earlier, low-fidelity stages of design. It will provide deeper insight into the user experience (UX) around the product. It also reduces the risk of errors in the production run, ironing them out at the prototype stage.

This is a great way to get buy-in from project teams based on a real-world, responsive example. The iterative capabilities of such a close approximation of the final product also make development faster.