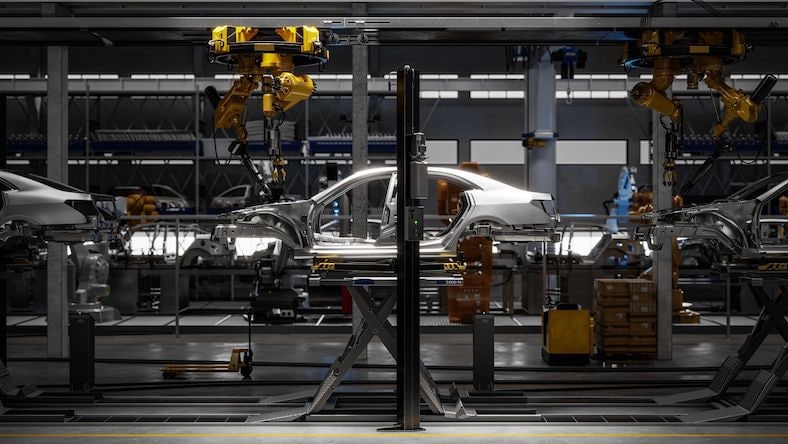

Industrial engineer and inventor Jerome H. Lemelson pioneered the concept of flexible manufacturing systems in the early 1950s with a series of patents for a robotic production system that would weld, rivet, convey, and inspect products. The concept was not practical until the 1960s but it proliferated in the 1970s. Since then, FMS have become more capable, adaptable, modular, and attainable for smaller-scale businesses. But regardless of the type or scale of FMS being used, the systems are all based on the three components of 1) a centralized computer and software controlling 2) work machines that manipulate 3) materials into parts or products. Elements of FMS include robotics systems for assembly, pick and place, inventory, and more; computer numerical control (CNC) machines and 3D printers; and programmable logic controllers (PLCs).

The “flexible” aspect of flexible manufacturing boils down to either routing flexibility or machine flexibility. Routing flexibility means that a business can rearrange the sequence of a product’s manufacture and assembly to adapt to changing circumstances. So, if a product takes several stages and workstations to completely produce and assemble, the company can re-order the sequence of work to keep production going if a supply disruption or machine maintenance affects one of the stages. With machine flexibility, a manufacturer can produce the same product using different machines, with minimal differences in the quality and details of the product. For example, if one machine needs maintenance or there is a sudden surge in demand, the company can shift production over to another machine or set of machines.

Several types of flexible manufacturing systems have been defined, but in the spirit of flexibility, manufacturers can combine them all as needed. A dedicated FMS focuses on a specific product that is highly specialized, which makes it common in high-performance industries like aerospace. A sequential FMS makes a product or group of products in a specific sequential order, moving from one station to the next. An engineered FMS makes the same part in high volume with high accuracy and is common in the automotive industry. Random FMS is the most common type and can adapt quickly to making different products with different specifications from the same machine or set of machines. Finally, a modular FMS is the most flexible type of system because it combines FMS elements from all the other FMS types to create workstation modules that can be configured, modified, and upgraded to adapt production lines radically using existing equipment.