-

Back

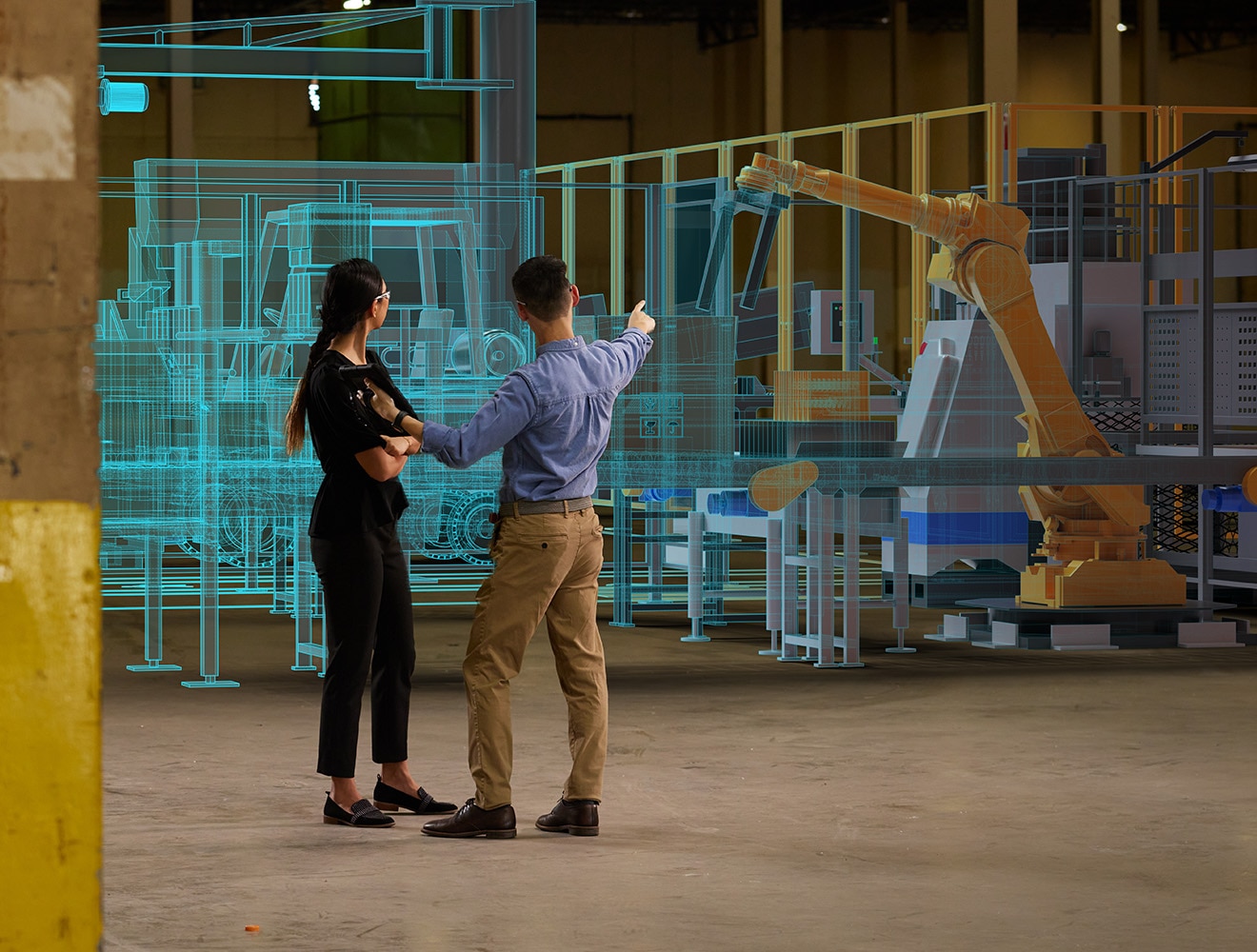

A digital factory is a shared digital model that gives you insights into how to design, build, and operate your facility, reconfigure it for product and process changes, and maximize overall efficiency and productivity.

From AI to automation to data-driven insights, today’s manufacturing tools and processes are more powerful than ever. Shaped by digital transformation, organizations are embracing the digital factory to connect teams throughout every phase of the factory lifecycle. Instead of siloed workflows, you get efficient collaboration. Instead of data loss between departments, you unlock better, more powerful insights.

With Autodesk digital factory solutions, you can translate factory design directly to manufacturing output. Increase manufacturing flexibility as you empower architects to co-create with production and manufacturing engineers, then help construction align with the evolving production line.

Put your plans into practice faster and more efficiently with Autodesk digital factory solutions. Share the same building information modeling (BIM) data with your production engineers, architects, building engineers, and contractors to accelerate construction and shop floor design.

The majority of a factory’s lifetime costs occur during operation, but often, crucial information is filed away in boxes. Autodesk digital factory solutions capture and connect your data in the cloud to document, track, and manage operations at every step.

Drive increased efficiency, throughput, and quality during manufacturing process development with powerful 2D and 3D CAD workflows that help you keep plans on track while optimizing your factory design.

Improve product development agility, increase innovation capacity, and expand product offerings with purpose-built tools and workflows that help you get your best ideas to market more efficiently.

Improve collaboration, reduce costly errors, and get your products specified in more projects through the same connected BIM ecosystem used by building and infrastructure customers.

Visualize your production processes and identify bottlenecks by modeling and simulating a variety of scenarios—and use the results to refine and optimize your factory design for increased manufacturing throughput.

Unlock resource planning efficiency, improve manufacturing flexibility, and increase throughput with advanced digital planning tools designed for all levels of manufacturing and production.

Make better informed decisions, improve your customer service, and reduce downtime with continuous, real-time data and virtual representations of real-world assets to help predict and optimize performance.

Improve collaboration, increase development agility, accelerate time to market, and deliver supply chain transparency—a single source of data, with multi-CAD integration, keeps everyone on the same page.

Reduce defects and nonconformities, improve the handover experience, and increase machine efficiency with a robust installation process when commissioning new machines for your factory.

Enhance efficiency, improve quality, and lower risk with one single source of truth that puts data at the center of the entire project team—from architects and contractors to engineers and facilities managers.

Digital factories enable cross-functional coordination, create greater agility to adapt to the changing world, and give companies a competitive edge. Learn how leading organizations are going digital to inform smarter decision-making across the value chain.

MANUFACTURING VISION

Hear Autodesk leaders predict how a thriving future will be powered by cloud-based platforms, AI, and highly connected workflows.

ARTIFICIAL INTELLIGENCE

FUSION INDUSTRY CLOUD

See how Autodesk's Fusion Industry Cloud accelerates digital transformation, centralizing project data for enhanced collaboration, efficiency, and innovation.

Talk to Sales today to learn how integrated digital factory technologies from Autodesk provide you with the critical information needed to better design, build, and operate your facilities.

A digital factory is a shared digital model that gives you insights into how to design, build, and operate your facility, reconfigure it for product and process changes, and maximize overall efficiency and productivity.

A digital factory provides each stakeholder involved with the critical information they need to better design, build, and operate their facilities.

Integrated digital factory technologies—like layout and design toolsets, simulation, data and process management, and digital twins provide organizations with the critical information they need to better design, build, and operate their facilities. Autodesk provides a comprehensive, robust, and integrated foundation of digital factory software including:

Integrated factory modeling (IFM) connects, organizes, and optimizes all phases of factory projects. IFM enables the convergence of information about the facility, such as Mechanical, Electrical and Plumbing (MEP) and all the machines in production lines. Through centralized management, data silos are removed, giving every team real-time data access for simplified collaboration and faster, data-driven decision-making. To learn more about how your organization can benefit from integrated factory modeling, contact your account team.

A digital factory solution can automate manual tasks, optimize production schedules, monitor equipment performance in real-time, enable predictive maintenance, and provide actionable insights for continuous process improvement.

Yes, a digital factory solution can be customized to meet the specific needs of various manufacturing industries, including automotive, electronics, pharmaceuticals, consumer goods, and more.

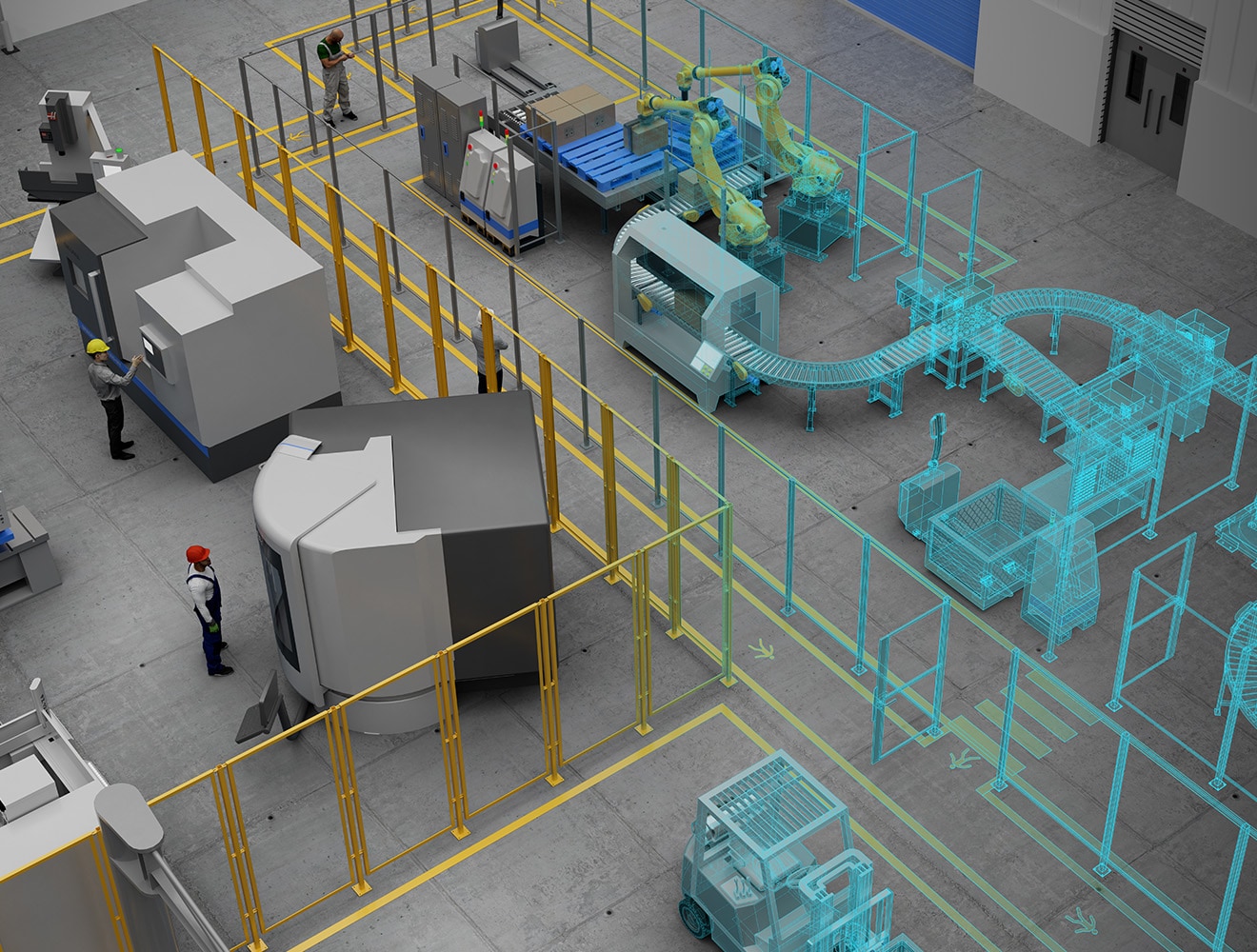

Digital factory software streamlines 2D and 3D workflows between multi-disciplinary project teams. For example, instead of designing a factory in AutoCAD and Inventor separately, you can simultaneously create a 2D and 3D model with appropriate level of detail with the Autodesk Factory Design Utilities. More advanced applications of digital factory software take advantage of interoperability between equipment models, factory layouts, reality capture data, and building models. All the data and processes are integrated in one digital factory model. At its most mature state, a model like this can be used as a digital twin for the production facility.

Similar to a digital factory, a smart factory relies on integration of equipment. However, a digital factory primarily refers to integration of all data and processes involved in a factory's lifecycle in one digital model, whereas a smart factory primarily refers to connections between equipment and computing systems, enhanced by automation, artificial intelligence and machine learning.

Digital factories are useful for accelerating the factory design process, catching errors like collisions between equipment and building features, improving collaboration across multidisciplinary project contributors, and creating digital twins to support factory operation.

The automotive industry is leading the way for digitalization of the factory, but there are many examples in other industries as well. Factory owners, equipment manufacturers, full solution providers, and even AECO firms are adopting digital factory solutions to drive business outcomes.

The automotive industry is leading the way for digitalization of the factory, but there are many examples in other industries as well. Factory owners, equipment manufacturers, full solution providers, and even AECO firms are adopting digital factory software to drive business outcomes. Autodesk customers who have embraced the digital factory include: