How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

Engineers program and train collaborative robots to operate directly with or close to human workers.

A cobot is a robotic system designed to work directly with or close to a human, harnessing the skills and advantages of both and ensuring worker safety through advanced sensor and materials technology. In contrast to classical robots, the emphasis with cobotics is on cooperation between machine and human.

Traditional industrial robots are caged or walled off because their rapid repetitive motions and heavy materials often pose a danger to operators and coworkers. By contrast, cobots in manufacturing add efficiencies and value by working directly with or sharing the workspace with human coworkers.

Cobots and people working together save space and reduce some of the cumbersome and expensive safety measures of traditional manufacturing. Integrating cobots into the workplace lets you design processes that combine the unique skills and abilities of human workers and robots to work faster and better.

Some industrial cobots merely share the workspace with a human without any direct overlap; some work in sequence with the actions of a human; and some react to a human operator’s work, responsively matching pace and output in real time. Consequently, collaborative robots are ushering in a new style of manufacturing that brings out the best in robots and humans.

In the past, robots have been involved in a variety of workplace accidents. Fortunately, industrial cobotics are a much safer proposition.

Designed to interact with humans, cobots are equipped with sensors to detect and prevent unsafe situations, with complex algorithms governing their interactions.

Like other robots, cobots can be used to minimize the exposure of workers to hazardous conditions, while maintaining a closer operational link in real time.

Cobotics can even help to ease the risk of repetitive strain—a constant issue in manufacturing environments.

Cobots have a modular nature and a footprint that’s usually smaller than that of industrial robots, offering compelling benefits for manufacturing.

Industrial robots can take weeks to install, program, and test, but with a far nimbler profile, a cobot can be set up to run within hours.

Cobotic solutions from today’s third-party providers come with easy-to-use cobot software. Many cobots are controllable from a mobile device, letting users outline and save actions easily.

Because of the speed of setup, cobots in manufacturing can be easily redeployed in other areas to perform different tasks in the production line or operating process.

Humans aren’t built for identical repetitive motions, which makes collaborative robots the ideal partner for taking over high-precision, repetitive mechanical actions in larger operations.

By far, the biggest advantages of human-robot collaboration are a rise in output, an increased production rate, and improved product quality.

Cobots are much easier to program than the robots of the past, thanks to user-friendly cobot coworking software. Autodesk PowerMill cobot software allows you to easily program your cobots for manufacturing processes such as 3- and 5-axis manufacturing, as well as offering advanced manufacturing capabilities via the Fusion Manufacturing Extension. You can optimize toolpaths quickly and easily, ensuring that your cobots stay in step with their human teammates. With Autodesk’s cobot software, you can work toward a future where robots and humans work side by side to accomplish great things together.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

There are four main types of cobots:

This is the most common type of collaborative robot, equipped with sensors to detect contact with a human and to stop if safe thresholds are breached.

This type of collaborative robot is manually controlled by human operators. It can be taught processes directly in this manner.

These cobots use laser scanners within operational set zones to detect the approach of a human worker and to slow down or stop entirely if within reach. As the person leaves, the cobot robot resumes work at full speed.

These cobot robots automatically detect when a person has entered a workspace and halt operations until they have left.

Cobots programmed to respond to the actions of a human coworker are tailor-made for AI. Machine learning makes cobots able to learn and perform new behaviors simply by observing their human coworkers. While traditional manufacturing robots follow programs for fixed behaviors like operating rate and sequence of movement, cobots with AI work very differently. Most significantly, cobots are capable of learning and adapting based on their exposure to humans and the working environment that surrounds them. The more experience a cobot has working with humans, the more data it has available to adjust its behavior using machine learning.

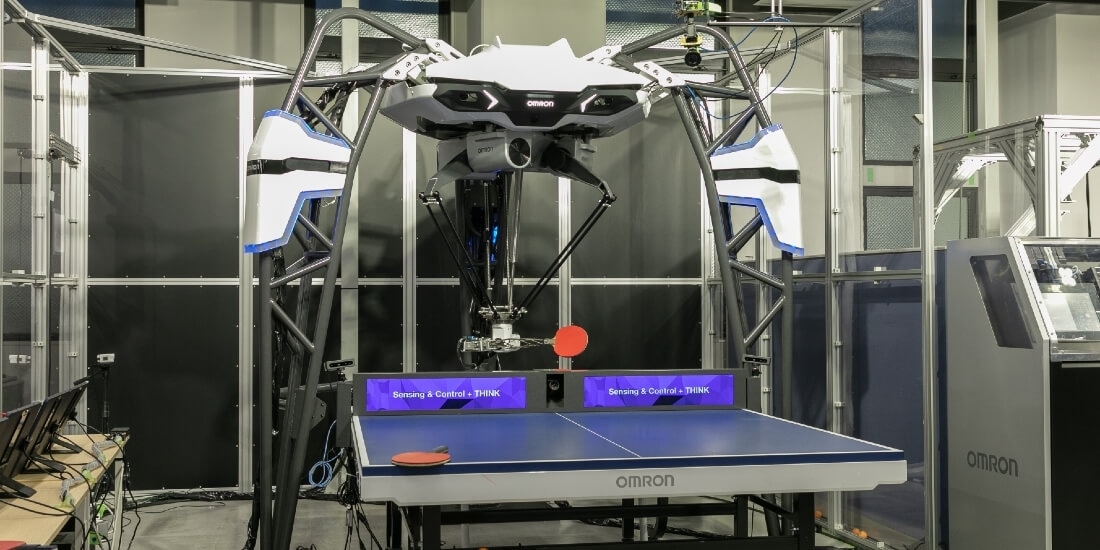

OMRON

Learn how Japanese manufacturer OMRON’s table tennis–playing robot is helping advance the collaboration between humans and machines.

ARROYO BRIDGE PROJECT

See how architecture students at USC partnered with Autodesk Research Robotics Lab to utilize collaborative robots in the fabrication of a 70-foot pedestrian bridge.

This primer on the new paradigms of cobots in manufacturing discusses industrial cobotics as a critical component of the factory of tomorrow.

Learn about current and past projects of the robotics team at Autodesk Research.

In this class from Autodesk University, learn about the toolset that is enabling and enhancing collaboration between human and robot workers.

Traditional industrial robots work alone in clearly established workspaces, often with a physical barrier safely separating the robot from the human team, performing strictly timed and programmed actions.

A cobot is a collaborative robot that works closely alongside or in a direct partnership with a human operator, whose safety is assured through sensor and materials technology.

So far, cobots have found homes in factory, site, and plant settings in manufacturing and construction where frequent, precise, and repetitive actions can augment tasks performed by human workers.

Industrial cobotics are designed to occupy the same physical space as human workers. Collaborative robots can carry out a role in the process without direct human interaction, or they can use sensory data to respond to human actions.