How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2024 Autodesk Inc. All rights reserved

CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling.

CNC programming involves writing a series of commands, typically in the form of a programming language, G-code, that specifies the actions the CNC machine should take. These commands include information about tool movements, spindle speeds, feed rates, tool changes, and other parameters necessary to carry out a specific machining operation.

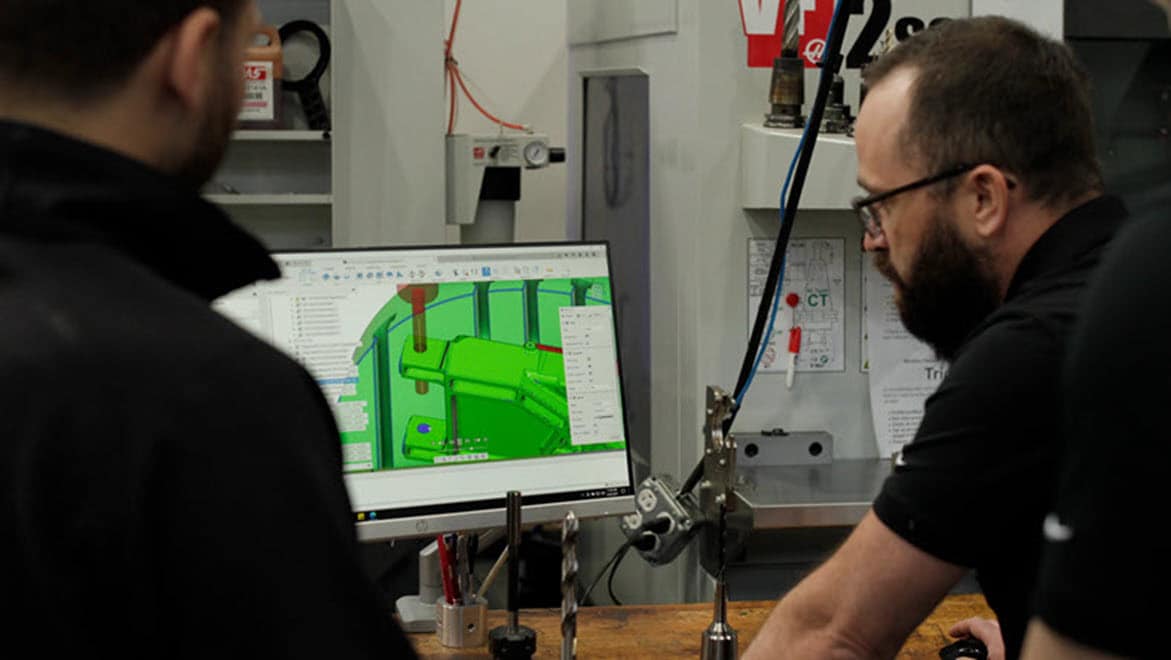

CAM software for CNC refers to computer programs that are used to create, edit, simulate, and manage CNC programs. CNC programming software tools provide a graphical interface and a range of features to facilitate the programming and control of CNC machines.

CNC programming software can vary depending on the machine type, manufacturer, and the specific needs of the user or organization. CNC CAD CAM software tools offer varying levels of functionality, compatibility, and ease of use, so it's crucial to select the appropriate software that suits the requirements and capabilities of your CNC machine.

A CNC (Computer Numerical Control) programmer is responsible for creating and developing the code that directs CNC machines to perform tasks like cutting, drilling, or milling materials. They interpret technical drawings and CAD models to understand the specifications of the workpiece, select appropriate tools and materials, and may assist in setting up and calibrating machines to ensure accurate operation.

CNC programmers also optimize machining processes to enhance efficiency and product quality, troubleshoot issues, and monitor the process to ensure it meets required standards. They collaborate with engineers, machinists, and other personnel to ensure smooth production and stay updated with the latest technologies and techniques for continuous improvement in machining processes

CNC programming is important because it empowers manufacturers to achieve higher levels of automation, precision, efficiency, and flexibility in their machining operations. It enables the production of complex parts with consistency, quality, and speed, making it a fundamental component of modern manufacturing processes.

Here are some top reasons how CNC CAD CAM software for CNC programming can benefit your manufacturing processes.

Perform complex operations automatically and with high precision, while reducing the reliance on manual labor, minimizing human error, and increasing productivity.

CNC programming allows for efficient use of machine time allowing for optimized toolpaths, minimized idle time, and reduced material waste.

Use the same machine to produce different parts simply by changing the CNC program. This versatility allows for quick setup and adaptation to changing production needs.

Once a CNC program is created and tested, it can be used repeatedly to produce identical parts. This is important in industries where precision and quality control are critical.

Once the program is set up correctly, the machine will execute the operations precisely as programmed, reducing the risk of mistakes caused by human factors like fatigue, inattention, or skill variations.

CNC programming allows for the utilization of advanced machining techniques and capabilities. This includes high-speed machining, multi-axis machining, adaptive machining, and complex tooling arrangements.

CNC routers are commonly used in woodworking and can range in size and style from a desktop 3-axis to a room-sized 5-axis configuration.

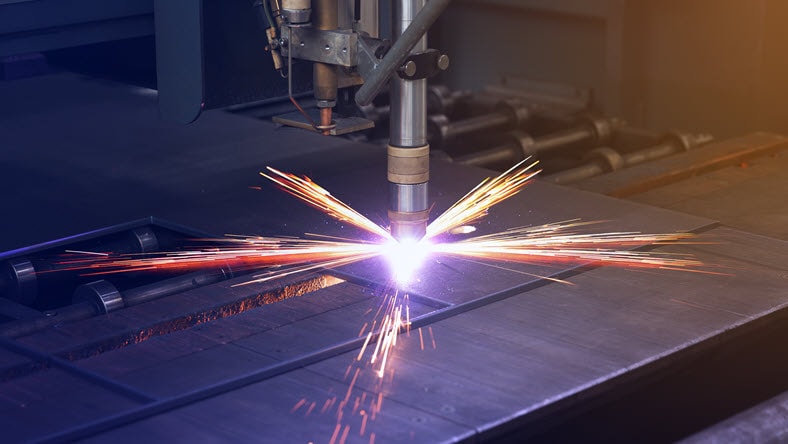

CNC plasma cutters are used to cut conductive metals using a jet of hot plasma. These CNC machines offer high precision at low cost.

Laser cutters can be used to cut various types and thicknesses of materials, even metal, depending on the power of the laser.

CNC lathes rotate the workpiece and apply various cutting tools to create parts with a revolved profile. These are often programmed by hand.

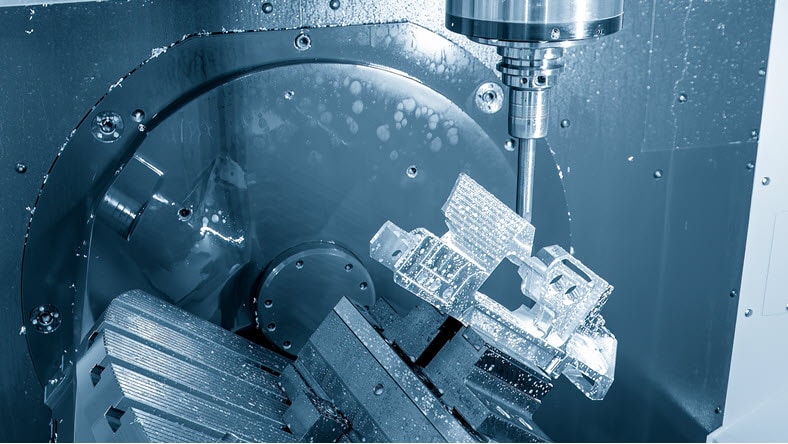

Mill/turn machines combine milling and turning into a single machining center. These machines can create spun profiles like lathes.

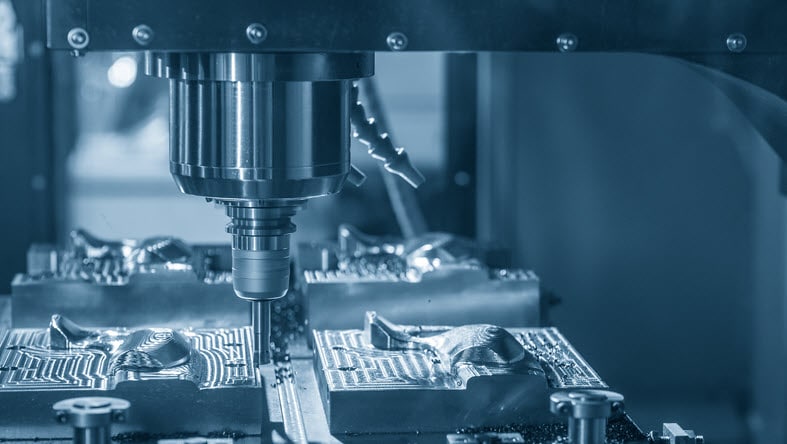

Milling machines are versatile and come in various configurations from 2- to 5-axis milling configurations.

Multi-axis milling is the addition of up to two rotational axes to a 3-axis milling configuration. This allows access to more of the part.

CNC waterjet cutters combine high-pressure water with an abrasive media to cut parts.

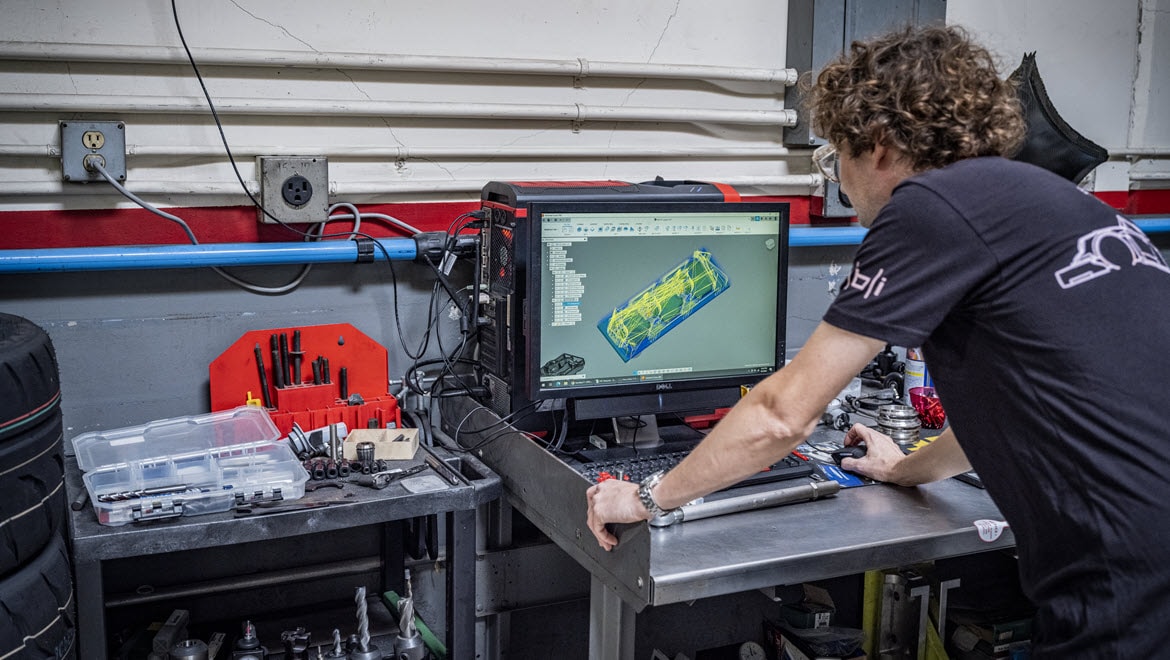

Fusion is commonly used CAM software for CNC programming and is known for its integrated CAD/CAM capabilities. Fusion allows users to design 3D models of parts and then generate toolpaths and G-code for CNC machining.

With Fusion, you can create and edit 3D models, define machining operations, and generate toolpaths for various CNC processes such as milling, turning, and routing. The software offers a range of CAM CNC features, including toolpath strategies, simulations, post-processing, and machine tool library management.

Fusion's CAM CNC functionality allows users to define cutting tools, set machining parameters such as feed rates and spindle speeds, select cutting strategies and simulate the machining process to detect and avoid collisions or errors. Once the CAM setup is complete, Fusion generates the corresponding G-code, which can be sent to the CNC machine for execution.

G-code is a programming language used to control computer numerical control (CNC) machines. It consists of a series of commands or instructions that tell the CAM CNC machine how to move, position, and operate its various components, such as the cutting tool, spindle, and auxiliary functions.

G-code commands are typically represented by a combination of letters and numbers. Each command has a specific function and is executed sequentially by the CAM CNC machine. The G-code commands cover a wide range of operations, including tool movements, spindle speed, feed rates, tool changes, coolant control, and more.

Unlock additional capabilities for 3 to 5-axis CNC machining, sheet-based nesting and fabrication, and metals-based additive manufacturing.

Learn about the top 8 milling tools that form the backbone of every professional CNC machining job.

Learn about the core component of every CNC program – G-code.

Explore the merits of 4-axis further, looking especially at its role in mill-turning.

Although EDM manufacturing is often valid, it’s important to explore whether some cases can be replaced with faster methods, such as CNC machining.

Learn the basics of the CNC coordinate system, including the Cartesian coordinate system, work coordinate system (WCS), and offsets.

Discover the ten most common types of fixturing and what type of fixturing is best for your milling project in this CNC fixturing overview.

Autodesk Fusion is a cloud-based 3D modeling, CAD, CAM, CAM, and PCB software platform for product design and manufacturing. It provides integrated CAD and CAM, CNC programming tools for 2D, 2.5D, 3-axis, 3+2, and 5-axis machining solutions. A range of subscription options exist, including a free option for personal use, a commercial subscription ($680 per year), and a range of Extensions to unlock additional technology to meet the needs of more advanced applications.

Computer numerical controlled (CNC) machine programming is a process whereby instructions are combined together to define how a CNC machine will move and function. By carrying out these instructions, the CNC machine will convert some form of raw material into a finished product. CNC programming can be used to drive a wide variety of different machine types, including; routers, mills, lathes, mill-turn and turn-mill machines, multitasking centers, wire EDMs (electrical discharge machining), and industrial robots.

Regardless of the type of machine being used, the instructions are typically provided in one of two ways, either; 1) via manual data input (MDI) using some kind of human interface built into the CNC machine, or 2) by producing a digital file using offline CAM (computer-aided manufacturing) software.

In recent years, there has been a substantial increase in part complexity. This, combined with an increasing pressure to improve part quality and increase overall operations effectiveness (OOE) has resulted in the most manufacturers moving away from manual (MDI) CNC programming and investing in CAM software.

CAM software, such as Autodesk Fusion 360, is used to create a digital file (NC program) that contains instructions necessary to control how the machine will function. The CAM software is used to define the entire machining process and often uses a digital twin of the machine, cutting tools, and work-holding that will be used. This "offline" programming allows the machining process to be developed away from the physical machine – meaning problems can be simulated and avoided long before they're run on the actual machine. The use of CAM software plays a major part in helping manufacturers to make better use of their CNC machinery, and to avoid costly machine down-time that would otherwise be caused by unnecessary data input.

There are three basic means of CNC programming:

1) Manual data input (MDI) – where a skilled operator will manually enter the various M-codes and G-codes to define the NC program. This kind of programming is best suited to simple parts.

2) using computer-aided manufacturing (CAM) – where dedicated CAM software is used to produce one or more toolpaths that will be used to machine the part. CAM software can export these toolpaths into NC programs that contain M-code and G-codes suited to run on a specific CNC machine. CAM software is best suited to more complicated geometry or applications – such as programming simultaneous 5-axis machines.

3) Conversational programming – whereby a machine operator uses predefined routines to carry out simple machining operations (for example using a wizard to automatically program a simple rectangular pocket). This kind of programming is best suited for simple parts.

An NC program typically combines G-codes and M-codes together to form a set of instructions that a CNC machine will carry out.

G-codes (or geometric codes) typically control how and where a machine should move (for example moving a linear/rotary axis from one position to another).

M-codes (or machine codes) are used to control different modes or functions within the machine (for example turning coolant on, loading a cutter into the spindle, activating the spindle and turning it clockwise, or controlling whether the machine should position itself using absolute or incremental mode).

The length of a CNC program will vary depending on the component that is being machined. As an example, a simple program that drills a few holes into a component may only be a few lines of code, it may be a few kilobytes in size, and will probably take a few seconds to generate within your chosen CAM software. As the size and complexity of a part increases, the CNC program needed to make it will correspondingly increase in size and the time needed to both calculate it and execute it on a CNC machine.

CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CNC (Computer Numerical Control) are interconnected technologies used in manufacturing. CAD software is used to create detailed digital models of parts, CAM software translates these models into machining instructions, and CNC machines follow these instructions to produce the parts with high precision and efficiency. This integrated workflow streamlines the design-to-production process, improving accuracy, reducing errors, and enhancing overall product quality.

A CNC (Computer Numerical Control) programmer plays a crucial role in the manufacturing industry. Their primary responsibilities include:

Overall, CNC programmers are essential in ensuring that CNC machines operate efficiently and produce high-quality parts in a cost-effective manner.